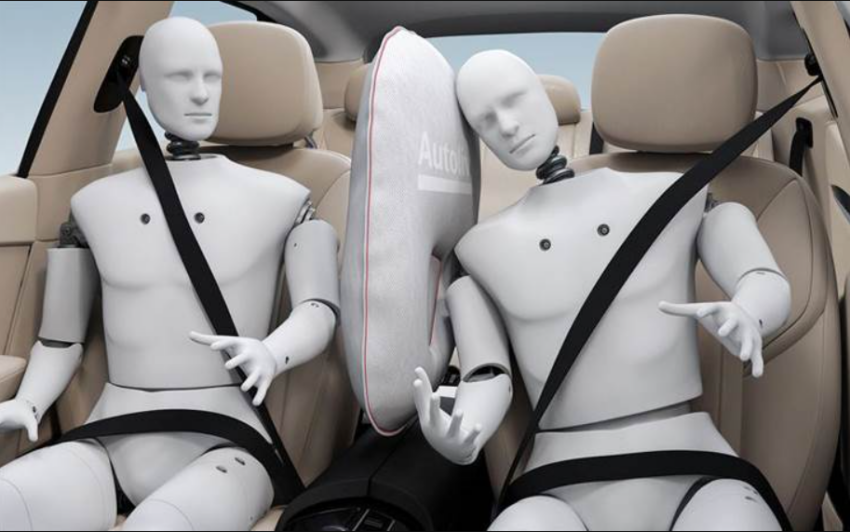

New airbag technology has been introduced by the safety equipment specialist provider Autoliv. The new technology is based on the Bernoulli Principle, which states that the static pressure of a fluid will drop as the speed of the fluid rises.

In the event of a collision, traditional airbags depend on the pressure of the gas contained within them to swiftly expand. However, the Autoliv design makes use of pressure differences to take in air from the surrounding environment, which speeds up the process of inflation.

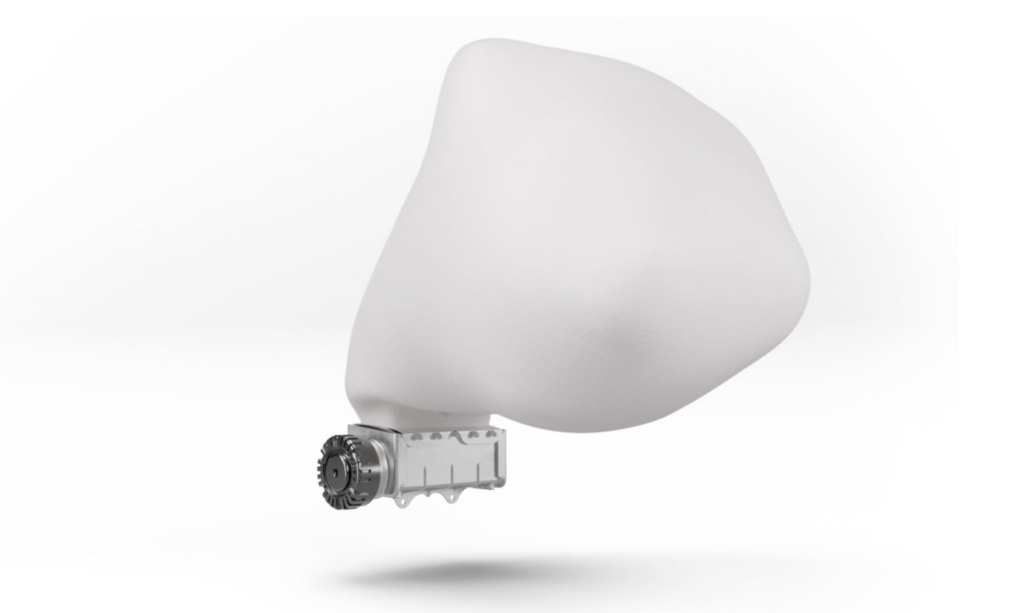

The innovative technique includes an inflator that is capable of receiving a signal indicating that a collision has occurred. After that, high-pressure gases are propelled at fast speeds through a number of different input tubes.

Pressure differences bring air in, boosting inflation.

As the gases move through the tubes, they produce a vacuum effect, which in turn generates aspiration by sucking in air from the surrounding environment.

Because pressure dynamics and aspiration work together, it is possible to inflate a bigger airbag with a less powerful inflator thanks to the combination of the two processes.

Autoliv believes that this results in enhanced efficiency while also drastically decreasing the amount of time and money required for development.

The Bernoulli airbag is more lightweight, produces less heat, and has the potential to cut customer development testing in the United States by as much as 30 percent. According to a statement released by the chief technical officer Jordi Lombarte, low risk deployment requirements may be satisfied using a single stage inflator.

In the third quarter of this year, original equipment manufacturers will have access to the new airbag.